Precious Forever

ROUGH PURCHASE & ASSORTMENT

Rough Purchase

The rough diamonds are sourced from miners in South Africa, Antwerp, Dubai and Russia through the big names such as DTC, Alrosa, Petra and ODC. After that, our well-defined quality control benchmarks help in classifying and grading the finished pieces.

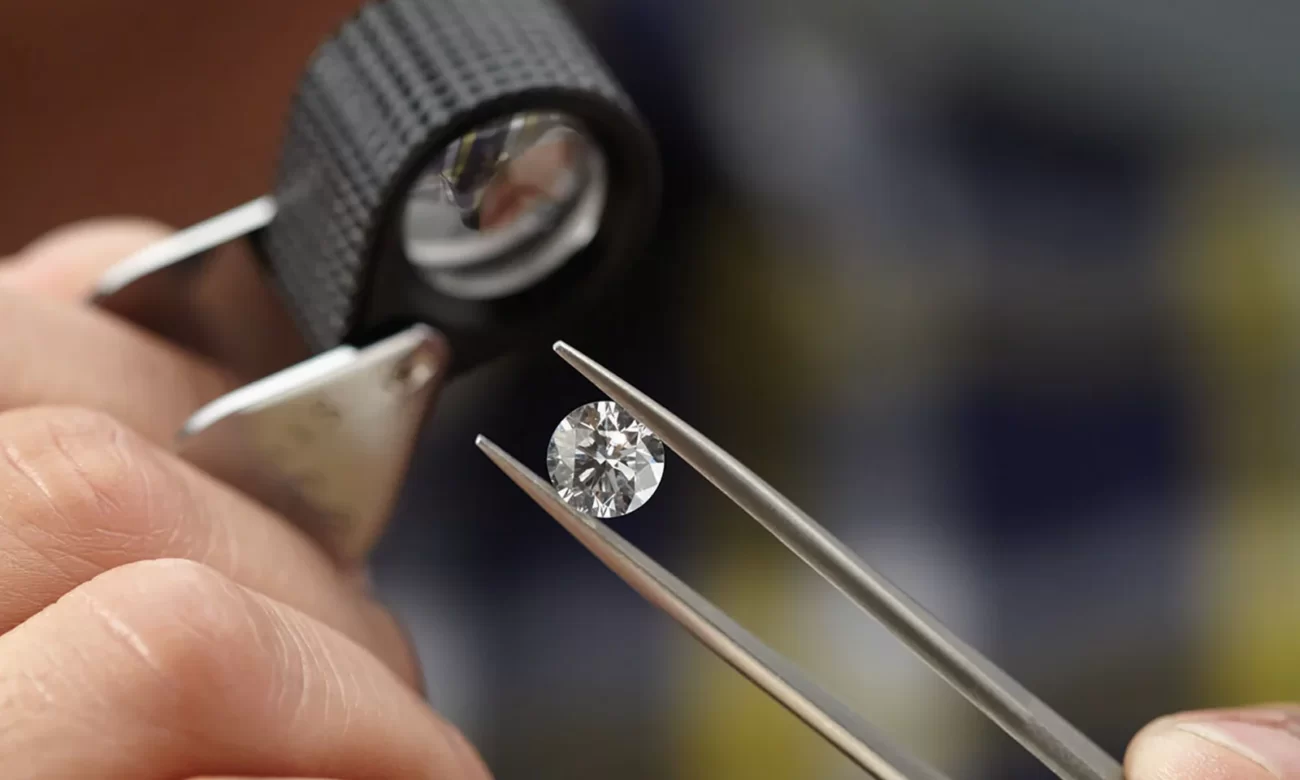

Rough Assortment

We ensure the polished outcome of a rough diamond. From examining the rough stone ticking all the right boxes (colour, clarity, carat and cut), our processes are well-defined. This department’s experts assort the rough diamonds into small packets. Every gem’s clarity is based on the number, location, size and type of inclusions in the stone. An inclusion is basically the imperfection in the stone that is only visible under the magnification of a Grader’s loupe. Once the assortment is done, it’s over to the planning and marking department.

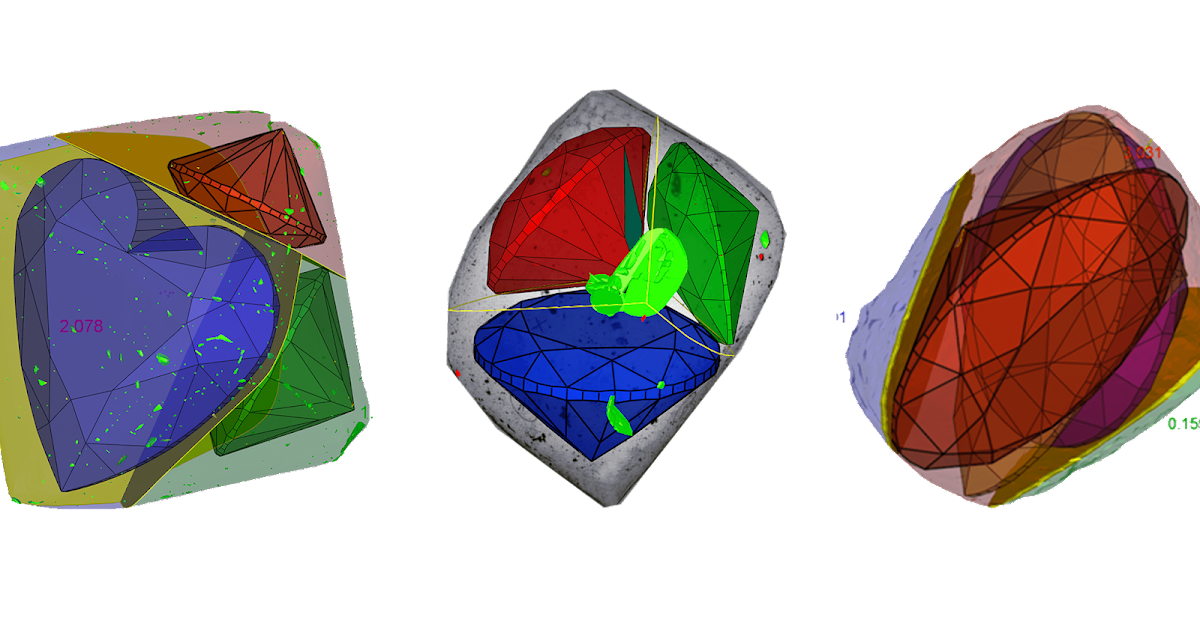

PLANNING

One of the most important departments of the entire set-up, it finalises the actual shape, size, weight, clarity of the diamond. Meticulous planning from our experts ensures the final output is fine-tuned and perfect.

Cleaving/Sawing

The rough diamond is cut into smaller pieces by cleaving (splitting the diamond along its natural planes of weakness) or sawing (using a diamond-tipped blade to cut the diamond). This process helps to remove any unwanted inclusions or flaws and to shape the diamond for further cutting.

Polishing

Diamond polishing shots are small, abrasive particles that are used in the process of polishing diamonds. These shots are typically made from industrial-grade diamond particles that are precisely graded to ensure consistent size and shape. The diamond particles are embedded in a matrix material, which can be metal, resin, or ceramic, depending on the specific application.

The main purpose of diamond polishing shots is to remove surface imperfections and enhance the overall appearance of a diamond. The shots are usually used in conjunction with a polishing compound or slurry, which is a mixture of abrasive particles and a lubricant. The slurry helps to carry away the removed material and prevents excessive heat buildup during the polishing process.

Diamond polishing shots are available in various sizes and grits, which determine the aggressiveness of the abrasive action. Finer grits are used for achieving a high polish and removing fine scratches, while coarser grits are used for initial shaping and removing deeper scratches or imperfections.

The polishing process typically involves placing the diamond and the polishing shots in a rotating container, such as a tumbler or a barrel. The container is then rotated or vibrated, causing the diamond and the shots to interact and abrade the diamond’s surface. This process is repeated multiple times, gradually using finer grits of diamond polishing shots until the desired level of polish is achieved.

It’s important to note that diamond polishing shots are primarily used in industrial settings, such as diamond manufacturing facilities or large-scale jewelry production. The process requires specialized equipment and expertise to ensure proper handling and achieve consistent results.

Grading

The final step in the process is to grade the diamond based on its quality and characteristics. This involves analyzing the diamond’s color, clarity, cut, and carat weight to assign it a grade and determine its value.